Rubber Tyred Container Gantry Crane Application Status and Development Analysis

Rubber tyred gantry (RTG) crane is a special type of gantry crane machinery used in container yard for container loading, unloading, handling, stacking and operation.At present, the lifting capacity of RTG crane is mostly 30st, the width is equal to the width of 6 rows of containers and 1 chassis lanes, the lifting height is generally 11-12 m. The main advantage of the rubber tyred gantry crane is that it can effectively utilize the yard, the construction cost of the yard is relatively low, flexible and versatile. It not only can move forward and backward, and is also provided with a steering device through 90 "wheel rotation, from a box area to another area of operation box.

Application status of Rubber Tyred Container Gantry Crane

With the increase of container throughput, on handling efficiency and economic benefits of increased demand, and development of modern science and technology, rubber tyred gantry crane develops rapidly. The following table lists the main technical parameters, driving and controlling modes of several kinds of container cranes produced in different years .

Seen from the table, RTG is developing to the direction of large scale, high speed, and modern type. With the development of modern science and technology, and wide application of electromechanical integration technology, there has been a radical change in the control mode of the rubber tyred gantry crane.

Characteristics of rubber tyred container gantry crane

In a narrow sense, logistics can be the flow of goods, this allows us to not deny the importance of transportation in logistics, while the use of containers is to make transportation more effective. It has some characteristics in container transportation:

- The walking track of gantry crane is directly laid on the work site, and the height of the track surface can be on the same plane as the work site. Therefore, storage area under the rubber tyred container gantry crane and the channel can be fully utilized.

- Rubber tyred container gantry crane does not have fixed permanent building, if the freight yard reconstructed and changed, the effect is little.

- The two end of most gantry crane have a cantilever with a length, the working area is enlarged, the goods allocation is fully utilized, what’s more, cars and other short distance handling equipment and railway vehicles can be directly loading, unloading and reloading, improved the handling efficiency, and accelerated the vehicle and cargo turnover.

- Rubber tyred container gantry crane has a certain mobility and is not limited by tracks.

Container throughput

In 2011, the volume of container cargo in major ports of the United States and Europe decreased sharply, while China's port container throughput increased by 11%, the container ports in China will go up in the opposite direction. The active maritime trade with emerging economies has directly contributed to the increase in the throughput of China's ports.

Seen from the proportion of port supply, the first 7 months of 2012, import growth is higher than export growth for the first time, thus effectively avoiding the decline of port volume due to the weakening demand of major economies such as Europe and the United States.

Led by Shanghai port, China's ports is upstream in the doldrums of global shipping, showing the trend of contrarian rise and rapid recovery. Statistics shows that in the first ten months of 2012 , China’s port have completed 13.49944 million TEU throughput of the international standard container, increase of 12.6% than that of the same period of the previous year. Among them, Shenzhen, Ningbo, Guangzhou, Qingdao, Tianjin and other ports container throughput showed a two digit growth.

Solution

The design prospect of rubber tyred container gantry crane without diesel generator set are becoming more and more practical, because of the use of a kind of electrical energy storage element. Use lithium iron phosphate battery to supply electricity, the transfer problem of rubber tyred container gantry crane has been fundamentally resolved.

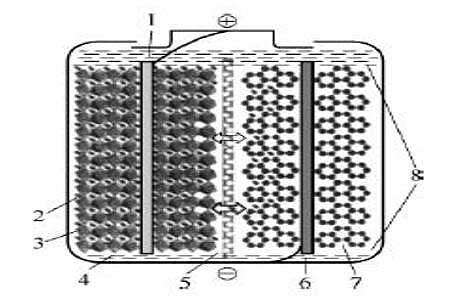

The internal structure of lithium iron phosphate power battery are shown in the above picture. On the left is LiFePO4 as the positive electrode of the battery, it is a olivine structure, which is connected by aluminum foil to the positive electrode of the battery, the middle is the diaphragm of the polymer, which separates the positive pole from the negative electrode, so that the lithium Li + can pass through, but electrons e- can not pass, the right side is the battery anode made of carbon (graphite), which is connected by copper foil. There is electrolyte between the upper and lower ends of the battery, the battery is enclosed in a metal enclosure. When charging, the lithium ion Li + in the anode of battery move to the cathode through the polymer membrane; when discharging, lithium ion Li + in the cathode of battery move to the anode through the polymer membrane. Lithium ion batteries are named after the move back and forth of lithium ions during charging and discharging.

Characteristics of energy-saving rubber tyred container gantry crane (green RTG )

The energy-saving rubber tyred container gantry crane (green RTG )has the following characteristics:

- There is no diesel consumption.

- There is no passive power consumption.

- There is no air pollution discharge.

- Noise pollution is reduced to the lowest level.

- No hydraulic contamination, that is, no hydraulic unit.

- The harmonic distortion rate of power supply meets the requirements of regulation and use.

- At least the cart motor and the trolley motor are driven by the permanent magnet synchronous motor, it is better if the lifting motor is also driven by the permanent magnet synchronous motor.

- The light emitting lamp adopts non inductance rectifier, use LED lighting.

- Minimize the maintenance of components on the rubber tyred container gantry crane.

To maintain the flexibility characteristics of gantry crane, a new automatic safety wire collector for power supply and power cut has been developed successfully by two German companies. The device does not need the assistance of the ground personnel, the power and power off of the safe slide line are completely completed by the crane operator in the driver's cab, and the operation of flexible transfer operation can be realized by using lithium iron phosphate power battery.

Development prospects of rubber tyred container gantry crane

Characteristics of lithium iron phosphate power battery

- Long service life. The service life of lithium iron phosphate power battery can up to more than 2000 times, cyclic capacity decay is less than 15%, the service life will reach 7 to 8 years.

- The use of lithium iron phosphate has been rigorously tested for safety, even in the worst condition of collision, extrusion, short circuit, it also won’t produce explosion and fire.

- The maximum discharge current can reach 10C and the starting current can reach 2C.

- High temperature peak of lithium iron phosphate battery is up to 350℃to 500℃.

- High stability, including high temperature charge capacity, good stability, and good storage performance.

- No memory effect.

- The energy density is large, so the volume is small and the weight is light.

- Its raw materials and discharge release is non-toxic, pollution-free, green environmental protection.

Configuration of lithium iron phosphate battery in rubber tyred container gantry crane

After equip lithium iron phosphate battery on rubber tyred container gantry crane, the safety, reliability and energy saving of the charging and discharging configuration should be fully considered.

- Security configuration. The safety of lithium iron phosphate power battery itself ensures the safety of use. Although the battery must be installed in the waterproof, sun protected metal box, the protection level of the box can not be designed too high, which is harmful to the heat dissipation of the battery. Therefore, the double-layer structure can be designed, and the outer protection grade is IP23, the inner layer is specially designed to prevent water droplets from passing through the outer layer and affect the battery operation.

- Reliability configuration. In order to ensure that the running bridge can work slowly t in the case of battery failure, we should design 2 sets of parallel battery charge and discharge unit. Once one set of the battery get out of order, the other set can ensure the crane to continue to walk at the speed of less than 30%.

- Energy saving effect. As long as the battery is in good condition, even in the non transition phase, PLC can also control to use the battery power to run the RTG crane, so that to maximize the energy efficiency.

- Electric control. The power supply system, PLC limit and sensor safety control circuit power supply adopts 24 VDC, the 24 VDC power provided by the dual power supply redundancy to ensure the reliability. One is provided by the battery, another is provided by UPS. Lighting, air conditioning and other auxiliary circuit are provided by variable frequency power supply units (about 32kVA). Variable frequency power supply is already a very mature technology product, it has been successfully used in metallurgy, telecommunications, post and telecommunications industry for many years, and has also been successfully used in port machinery. The configuration is as follows.

Predictably, the practical application of permanent magnet synchronous motor and the application of lithium iron phosphate battery will be realized in the same period, and this period will come in a few short years. Then, the use of diesel generators in the rubber tyred container gantry crane will become history, and then usher in a super green RTG Era.The future of RTG crane will become better and better.

Conclusion

With the increase of container throughput, improve requirements of handling efficiency and economic benefits, and the development of modern science and technology, rubber tyred container gantry crane have developed rapidly. The rubber tyred container gantry crane is developing towards large scale, high speed and modernization. The design of rubber tyred container gantry crane without diesel generator set is becoming more and more practical, because of the use of a new kind of electrical energy storage element. Use the lithium iron phosphate battery to provide electrical energy, the transfer problem of rubber tyred container gantry crane has been fundamentally resolved.