Multipurpose Rubber Tyred Gantry (RTG) Crane Design

Rubber tyred gantry crane is a kind of yard handling equipment which has been developed since 70s, it not only has the general characteristics of general rail gantry crane, large yard and high work efficiency, but also has the mobility of general rubber tyred crane. TICO rubber tyred gantry (RTG) crane can operate flexibility in a wide range, it has the characteristics of high space utilization, high productivity, and the whole yard maneuver.

Overall design of rubber tyred gantry (RTG) crane

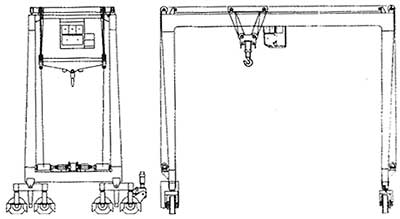

Figure 1 general layout design of multi-purpose rubber tyred gantry (RTG) crane

Analyzing and comparing the performance of similar model in foreign countries, on the basis of technical characteristics from RTG crane, container crane, and other reference professional straddle port handling equipments, optimizing the main parameters of equipment by applying the computer simulation technology, TICO can design the multipurpose RTG crane is more reasonable match between the parameters and strengthen the rationality of technology.

The general layout design of multi-purpose rubber tyred gantry (RTG) crane is shown in Figure 1. The main design specifications are shown in table 1.

In the general design of multi-purpose rubber tyred gantry (RTG) crane, lifting mechanism and operation mechanism used for goods lifting and trolley running share a set of driving device, which is arranged on the bottom beam of the structure. No power device is designed on the running trolley, the quality of the trolley is reduced greatly, which is the premise of the overall optimization of the whole structure.

The optimization design for metal structure applies the finite element analysis technology, make the whole structure to achieve the target of light structure and small quality under the condition that the RTG crane meets the requirements of cargo handling and stacking.

Bridge of the adopts tubeless tire, which can meet the requirements of mobility handling. TICO rubber tyred gantry (RTG) crane adopts frequency control mode, correct deviation in the running process, control deviation during operation, reduced tire wear and improved work efficiency.

table 1:| Lifting Capacity | 35 t |

|---|---|

| Lifting Height | 12 m |

| Minimum Running Design of Trolley | ≥11.5 m |

| Span | Center distance between two wheels is 17 m |

| Base Distance | 6.8 m |

| Lifting Speed | 12 m/min |

| Running Speed of Trolley | 36~48 m/min |

| Running Speed of Bridge | 40 m/min |

| Working Power Supply | Three phase、380v、50Hz |

| Power Supply Mode | Diesel generating set or cable drum |

| Electronic Control Mode | AC variable frequency drive |

| Wheel Pressure of Bridge | ≤20 t |

Whole rubber tyred gantry (RTG) crane structure design

TICO multi-purpose rubber tyred gantry crane adopts double gantry frame type structure, each frame is composed of a main beam and two legs, between two pieces of frames connect through the lower part of the bottom beam and the upper part of the beam, formed a solid metal frame structure, the structure of the components are connected by welding or flange. Metal structure using level is U5, load level is Q3, work level is A6.

The main girder is one of the main force components of the crane, shich adopts welded box structure. Running truck of rubber tyred gantry crane are laid on two main girders, its laying position is in the center of the main girder section, which is a box girder. According to eh requirements of different customers, the running truck of RTG crane trolley can also be laid on one side of webs of the top flange, which can be designed into deflect truck box girder. Similar to lifting capacity, the span is 23.47m. compared with standard bridge crane, the main girder of our multi-purpose rubber tyred gantry (RTG) crane has the characteristics of small size of section, thick plate, little longitudinal bars, the height of girder is 1/3 more than standard bridge crane, greatly reduced the structure weight.

Main mechanism design for RTG crane

Running bridge design for RTG crane

There are four sets of operating mechanism for RTG crane running bridge, two sets of which are driven mechanism, and the other two sets are driving mechanisms. The operating mechanism of running bridge is composed of a wheel set, a driving mechanism, a frame, a balance beam and a safety protection device.

The wheel set is composed of a tyre, a wheel rim, a wheel shaft and two bearing seats. Due to reduced friction between the tyre, tubeless tire has a good heat dissipation and long service life. The driving mechanism adopts a horizontal or vertical electric motor, driving wheel to drive wheel shaft on large chain wheel through reducer, chain wheel and driving chain. The driving part is provided with an adjusting device, which is used to adjust the tension of the chain. the frame is saddle shaped structure, which is connected with the balance beam through a flange or a rotating shaft, the lower part of the rotating shaft is provided with a thrust bearing to bear wheel pressure, and the upper part is provided with a thrust bearing, and a spherical roller bearing is adopted partly. Steering system using right angle steering, at the two ends of the yard, the steering auxiliary lifting device is adopted. When the steering wheel is turned on, the steering resistance and the deformation of the tire are reduced, after turn to the right direction, and then turn wheels in the right place.

Running mechanism and lifting mechanism design for trolley of RTG crane

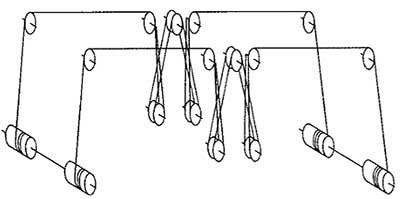

Figure 2 Wire rope winding system design

TICO rubber tyred gantry (RTG) crane adopts four drum operation design mode, running mechanism and lifting mechanism of the trolley share the same set of device. The mechanism is fixed on both sides of the bottom beam. In the trolley of the track of the main beam, only the lifting pulley block, the trolley wheel and the horizontal wheel are installed, no power device.

The running mechanism of the trolley and the lifting mechanism is composed of an electric motor, a coupling, a reducer, a brake, a low speed shaft coupling and a drum. Symmetrical arrangement of two sides mechanism. Wire rope winding system is a special designed wire rope winding way, ensuring that the container will not drop when a single wire rope fracture. The joint on fixed end of the steel wire rope is designed to consider the hinged form of the two running direction of the crane bridge and trolley. The wheel of our rubber tyred gantry crane is made of steel, double wheel edge, the tread is treated by hardened process. Guiding mode is that arrange horizontal wheel on outside of the truck, the guiding direction of horizontal wheel not only can provide the rail gnawing, but also can prevent the trolley from falling, providing the reliability of operation. Other devices include deceleration limit switch on the starting point and stop limit switch on the final destination.

Attachment

TICO rubber tyred gantry (RTG) crane adopts 35t forging hook, which can be used for loading and unloading of general cargo. If replacing a C shape hook, it can be used to handing the steel coil. Due to the large distance between the wire rope, lifting lugs are equipped on each corner of the cradle, so that the RTG crane can be designed to load and unload the logs and long steel section. What’s more, horizontal beam of the hook can be disassembled, in order to install the special sling of container, which are used for stacking and unloading of container.

Electrical system

Our rubber tyred gantry (RTG) crane can adopt diesel generating set or cable drum power supplying mode, the electric system adopts the full AC frequency conversion drive, which has good speed performance, perfect protection function and so on. Lifting mechanism not only needs a wide range of speed regulation performance, but also requires a high torque at low speed, therefore, the lifting mechanism adopts closed loop vector control mode, using high precision incremental encoder as feedback device of frequency converter. Trolley mechanism adopts the same control device with lifting mechanism, through corotation and reversal of two sets of inverter control motor, to achieve the forward and backward, rise and fall control of trolley.

TICO excellent rubber tyred gantry (RTG) crane design service

Through the serialization design of parameter for rubber tyred gantry (RTG) crane, our RTG crane design can meet different requirements of power supplying modes, types, lifting capacity and span. Thanks to professional rubber tyred gantry (RTG) crane design, TICO RTG crane can be widely used in loading, unloading, and transfer for medium-size and small-size container and cargo. If you have any need, please feel free to contact us directly, we will do our best to help you!